Meterial Engineering

-

We provide end-to-end industrial automation solutions based on PLC, HMI, SCADA, motion control, and field automation for manufacturing plants, process lines, and custom machinery.

-

We deliver vendor-independent, scalable, and reliable automation architectures for CNC machines, liquid filling and packaging lines, conveyor systems, robotic cells, and custom process equipment.

-

We actively work with the following PLC platforms:

-

Siemens (S7-300, S7-400, S7-1200, S7-1500 – TIA Portal)

-

Allen-Bradley / Rockwell Automation (CompactLogix, ControlLogix – Studio 5000)

-

Schneider Electric (Modicon M221, M241, M251 – EcoStruxure)

-

Omron (CJ, CS, NX – Sysmac Studio)

-

Mitsubishi Electric (FX, Q, iQ-R Series)

-

Beckhoff (TwinCAT – PC Based Control)

-

Fanuc PLC & CNC control systems (Fanuc PMC, Fanuc Ladder, CNC-PLC integrations)

-

Delta / Fatek and other industrial PLC solutions

-

-

Our PLC software is developed in compliance with IEC 61131-3 standards using Ladder (LAD), Function Block Diagram (FBD), and Structured Text (ST).

-

We implement modular software architecture, advanced interlocks and safety logic, alarm and fault handling, PID control, process regulation, and servo / motion control integration.

-

HMI and SCADA solutions are developed using Siemens WinCC / WinCC Unified, FactoryTalk View, Schneider Vijeo / EcoStruxure, Weintek, Pro-face, Ignition SCADA, and AVEVA Wonderware.

-

Full process visibility is ensured through recipe management, alarm and event logging, trend analysis, reporting, user access control, and multilingual interfaces.

-

Industrial communication protocols including PROFINET, PROFIBUS, EtherNet/IP, Modbus RTU / TCP, EtherCAT, CANopen, RS232 / RS485, OPC UA, and MQTT are supported.

-

Functional safety solutions are implemented using Safety PLCs, emergency stop systems, light curtains, and safety relays in compliance with EN ISO 13849 and IEC 62061.

-

System retrofit, modernization, energy efficiency improvements, and remote monitoring / control infrastructures ensure maximum production continuity.

-

All projects include commissioning, IO checks, loop tests, and site acceptance tests, supported by 24/7 technical support.

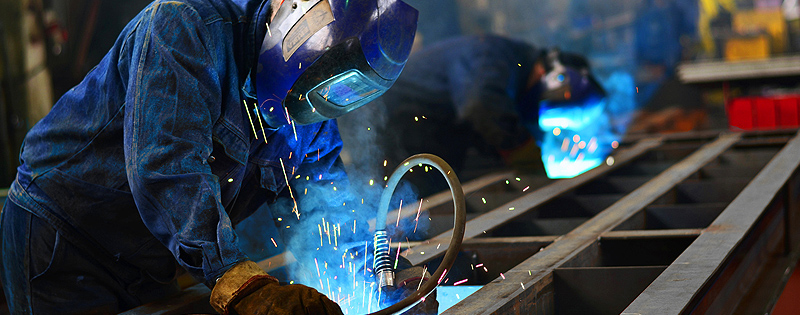

Our Workshop

-

In our workshop, we perform end-to-end processes including control panel design, electrical assembly, field wiring, and system integration for industrial automation projects.

-

PLC control panels, MCC panels, and field distribution panels are manufactured and tested in compliance with IEC, CE, and industrial safety standards.

-

All systems undergo IO checks, loop tests, and functional tests prior to commissioning to ensure readiness for site installation.

-

HMI and SCADA applications are tested in simulation environments before on-site deployment to minimize potential risks.

-

Industrial communication infrastructures (PROFINET, EtherNet/IP, Modbus, Profibus, RS485, etc.) are configured and validated in the workshop.

-

CNC systems, PLC integrations, and PMC ladder applications are prepared through comprehensive workshop testing.

-

Energy monitoring, remote access, and data acquisition systems are pre-tested to reduce commissioning time on site.

-

Our workshop processes are planned to ensure minimum downtime and maximum system reliability in the field.

We Are Dedicated To Our Work

-

At Arcomes Engineering, we approach every project with a strong sense of responsibility and engineering discipline.

-

We understand the critical nature of industrial production processes and therefore provide 24/7 technical support.

-

We respond rapidly during failures, retrofits, and commissioning phases to minimize production downtime.

-

We develop customized solutions tailored to specific customer requirements rather than relying on standard approaches.

-

We aim for long-term partnerships and prioritize system sustainability and long service life.

-

Transparent communication, documentation, and technical reporting are ensured throughout all project stages.

-

Reliability, continuity, and fast response times are the core principles of our on-site and remote support services.